Education faces the challenge to keep up with social and technological change in terms of professional learning content, and pedagogical development. Changes are not new, but the pace requires a clear vision to prepare teachers and trainers for changes in their profession.

Traditional forms like workshops and training courses do not provide the current possibilities which technology offers to support a tailored learning. New technologies use correlates with quality and effectiveness in education. Therefore, a learning lab is the place to be.

The lab introduces teaching personnel to support education and educational innovation. It is the place to experiment with new forms of education with ICT and to develop learning materials for trainings with learners.

The transnational EU project “DIOS – didactic innovation labs” develops, tests, evaluates and transfers digital enriched teaching and learning scenarios. Digital enriched means integrating technologies like Augmented Reality (AR), Virtual Reality (VR), IoT (Internet-of-things) and 3D printing in existing practical training environments in chemistry, mechatronics, and IT.

The project consortium consists of VET providers from Czech Republic (SPSCH Pardubice), Cyprus (SCP School of Certified Professionals), Germany (SBG Dresden), Netherlands (Graafschap College), and Slovenia (School Centre in Kranj).

During the two years runtime of the project, from 11/20-10/22, the project partners develop didactic guidelines, tailor-made AR, VR, 3D-printing and IoT enriched teaching and learning scenarios for the focus industries. These scenarios and more offers will be integrated in the planned learning labs for a modern and tailor-made ICT enriched training of teaching personnel in the participating institutions.

The real and the digital world overlap every day more and more. The use of smartphones and tablets enriches our daily communication at work and in the private life. The application of interactive 3D objects (= holograms) provides the floor for integrating them in professional guidance and in the explanation of non-visible processes. To see holograms, specialised technology, like smart glasses (Augmented reality glasses or AR glasses), smartphones or tablets are necessary. The use of smart glasses allows a hand-free use.

Currently less experiences exist to apply AR practical training.

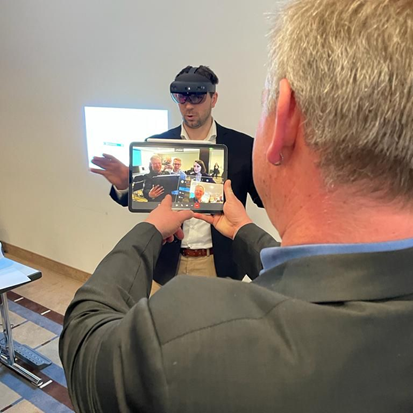

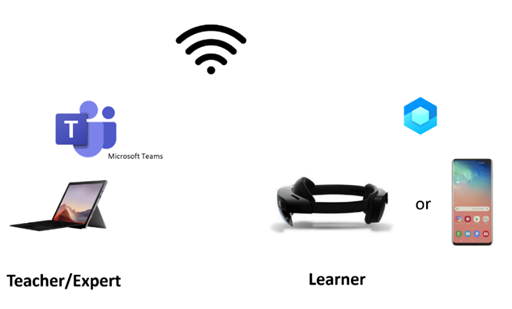

Augmented reality is at its best when providing technical and procedural knowledge like assisting in real-time when e. g. dealing with hazardous substances. The so-called AR remote support enables the expert to provide through audio-visual support by voice and by holograms, in a kind of livestream, professional guidance to the learner during training. The necessary hard- and software is shown below, when working e. g. with Microsoft products.

Example of AR remote training in chemistry:

For complex situations interactive AR digital twins or interactive digital copies of real objects, e. g. machine is suitable. Normally no tailor-made solutions are available. So, they must be programmed by a software programmer.

What a learning lab look like and how it is operated. On 16.09.2021 the management staff like directors and department managers of the DIOS partners were guest at the learning lab STRAX. The Dutch lab is associated with the Graafschap college, which is partner in the DIOS project. During the visit, the concept of providing tailorized and ICT enriched trainings for teaching personal and learners was shown.

The collected experiences provide the floor especially for the creation of the learning labs in Germany, Cyprus, Czech Republic, and Slovenia. It is expected that the involvement of the partners top management will provide a deeper understanding to them and results in further strategical and practical support during the realisation of the learning labs for chemistry (Lab: CZ, plant: Germany), mechatronics (Slovenia) and IT (Cyprus). The Dutch partner will extent through the DIOS project its learning lab offers concerning VR use in mechatronics.

The pedagogical sound uses of immersive media, such as Augmented and Virtual Reality, as well as 3D printing and IoT is new ground. We drafted first ideas who and where these scenarios do make sense (and much more).

Didactic-guidelines_update.pdf

From 18. and 19.11.2021 the partner organisation in DIOS from:

met during a hybrid meeting in Kranj/Slovenia to discuss learning scenarios and the setting of five different learning labs for chemistry (lab + plant), mechatronics (SI and NL) and IT.

The result of the meeting are roadmaps for the realisation of AR, VR, 3D-printing and IoT enriched learning scenarios for practical training in the frame of structured qualification programme (learning labs) in the DIOS organisations.

Applying modern media in practical training

WHY?

Chemical operators run and maintain chemical plants. They also must know about shredding operations of raw materials to reach a certain grain size. The understanding and operation of shredding mills is essential for it. For that documented and non-documented knowledge is a role.

SBG Dresden has 11 mills nearby its chemical training plant. The individual instruction of the apprentice by the trainer is time-consuming. A modern provision and on-the-spot guidance is required.

WHAT?

The application of the Microsoft Guides (“step cards”) and Microsoft HoloLens 2 were used to provide guidance on how to operate the cutting mill. The step cards were enriched with pictures, short videos, and verbal instructions.

HOW?

The apprentice used the Microsoft HoloLens 2 glasses during the operation of the cutting mill until successful completion (see the link to the video below)

EVALUATION:

Step cards a good method for self-paced learning for the provision knowledge from formal and informal contexts. The step-by-step virtual guidance provides a real-time evaluation.

The preparation of each step and the enrichment with digital media should be carefully planned by involving experts for cutting mills and pedagogues. It ensures a focussed and a pedagogical-sound application of smart glasses and the step cards along the desired learning path.

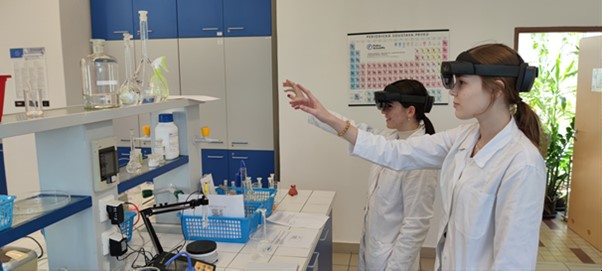

Within the DIOS project, SPSČH Pardubice focused on the preparation of a didactic innovation lab for teaching laboratory exercises in analytical chemistry using modern technologies. The technologies used are Augmented Reality (AR) glasses and intelligent sensors (IoT) as well as

360 ° videos.

SPŠCH is preparing a scenario in the field of instrumental analytical chemistry (instrumental analysis) for testing AR in teaching. Microsoft HoloLens 2 glasses play a key role in the preparation of the desired learning scenario. A step-by-step guide for the instrumental analytical laboratory was prepared using the software Microsoft Dynamics 365 Guides.

This scenario is complemented by audio-visual material, which used, among other things, 360° videos. Students and teachers, who had the opportunity to try this new way of teaching laboratory work, were accompanied by holographic cards with interactive content.

A huge advantage of this technology is the possibility of absolute control of individual holographic steps of the manual using voice, eye tracking or simple gestures. These features give the possibility of free hands for the work itself.

In addition, the holographic guide can be placed anywhere in the AR area of the laboratory, and therefore the subsequent view of the workplace is unobstructed and almost identical to that without glasses. The user obtains interactive instructions and necessary steps to carry out the professional tasks in the lab. Paper based instruction is not needed.

The last part of the scenario will be the connection of analytical sensors (conductivity, pH, temperature probe) with the AR glasses and the assembly of IoT, where it will be possible to read real sensor data directly in glasses. Later, it will be possible to influence the data at the same time and therefore advanced two-way communication will be established.

Within the DIOS project, SCP – School of Certified Professionals will focus on delivering the so-called innovation lab for Information Technology training (ICT) using edge technologies. The technologies used by our Training centre are Mixed Reality (MR) and the Internet of Things (IoT), the Microsoft Step Cards, as well as the remote assist. The combination of IoT and Mixed Reality will provide the user with data in a mobile and hand-free experience, as seen in figure1.

Our pedagogical application in training will provide insights through data visualization using technologies such as Mixed Reality (Microsoft HoloLens); the technology will help our trainees to reflect on the data presented. IoT with smart glasses enables our trainees to visualize and control a holographic dashboard. The combination of IoT and Mixed Reality and their synergically technologies such as Remote Assist and Step cards will add to the general pedagogical methodology that we will use in our innovation lab. Remote assist, a tool that provides assistance in the combination of a computer and a mixed reality headset in remote location, can be of critical value, especially when remote assistants (visualization and guidance) are needed. For example, a major server in a remote location is down, when a person at remote site needs assistance from an expert in the field, the expert can connect seamlessly to the MR glasses and guide that person, this procedures help minimizing the downtime of crucial infrastructure downtime.

School Center Kranj is a vocational high school that aims to use modern technologies and improve learning in the classroom and online. Learning should also be fun and engaging. 3D printing is a technology that enables educators to design rich learning experiences for deep theoretical constructs that bring learning from the computer screen into the hands of students.

In the last decade, 3D printing has made great strides that have lowered the price of the technology while making it more powerful and reliable than ever. It’s not just the financial hurdles that have dropped, either. The knowledge requirements have also decreased significantly. Gone are the days when operating a 3D printer required almost as much expertise as designing and building one.

Today, anyone can operate a printer, follow instructions and troubleshoot some basic errors. This means that your students can use the printers directly, without needing a trained professional to hold their hand through the entire process. And because the reliability of the printers is higher than ever, ongoing maintenance is much lower.

Schools are still in the early stages of adopting this innovative technology, but the exciting part is what’s to come. 3D printing offers several features that can revolutionize education, here are a few:

It provides more room for interactive classroom activities. For example, in biology, teachers can create a 3D model of the human heart, head, skeleton, etc. to help students understand the human body. When using a 3D printer, you can print with an incredible range of materials. Not only different types of plastics, but also metal, carbon fiber filled filaments, and more.

This is so beneficial because the applications for 3D printing are endless. Anyone who knows what a 3D printer can do can imagine how it could be useful for engineering or design. But there are also credible and demonstrable ways that 3D printing can help students in subjects like biology, geography, math, chemistry, history and vocational subjects like mechatronics, robotics and electro engineering. 3D printing is the ultimate cross-curricular technology, and the only limit to how it can be used is the imagination of your staff and students.

With the help of the DIOS project, we want to set up a room in SC Kranj where teachers can learn about new technologies.

We first started with a presentation of 3D printing and held a workshop, which was met with great interest. We presented the possibilities of using a 3D printer in various subjects. We are preparing a learning lesson for the use of a printer in the mechatronics program, where students can prepare a project in which the use of a 3D printer is an essential part.

Finding solutions for everyday and unusual problems is one of the tasks of students Mechatronics and ICT students. To practice this during their studies, learning arrangements have been made in the LearningLab STRAX of the Graafschap College. Such a learning arrangement consists of a practical situation that must be solved using IOT. In addition to devising a technical solution, attention must also be paid to the design. Both the design and the technology must be realized. Examples of practical assignments are an automatic watering system for the park that is resistant to vandalism, a desk lamp that adapts to the working conditions and a wireless camera system for reflection purposes in our concept store. Here is a short description of the camera project in our concept store “Details”.

Assignment

Design a system where students can make retail recordings of the sales conversations, they have that enable them to reflect afterwards on how the customer contact went.

Demands

The store consists of several areas. The cameras must have a solid and neat design and not disturb the view in the store. One of the cameras must work wirelessly because laying wires to this location is not possible. This camera is in the shop window and in full sun and must therefore be able to dissipate its heat well.

The cameras must be linked to OBS-Studio, which allows students to select scenes themselves for their reflection.

Realization

For this we interview Steve Bussing student ICT at Graafschap College.

“It was quite a challenging assignment because the design had to look good and work wirelessly. I opted for a sleek design in which the Graafschap College logo is clearly visible. To make sure the Raspberry Pi doesn’t overheat, I designed a sufficient opening on the front and back. I did this in Fusion 360. An additional problem was that the mini camera for the Raspberry Pi could not be delivered due to the Covid crisis and other logistical global problems. I was forced to integrate a Microsoft webcam into my design. In the end, this resulted in a good picture. For the app I chose and adapted open-source software. It is now intuitive to use and one-line to install. Then it’s just turn on and work. The connection to the computer with OBS-Studio is established automatically. Ok thought it was an interesting and instructive project from which I learned a lot. It is nice to see that your solution is being used.”

For more information, see the video https://youtu.be/U-Q_HT0GKhY

The provision of knowledge from expert to learner in practical training is often a mix of verbal and paper-based instructions. This process is time-consuming.

A guided, but self-directed way of learning allows step cards in combination with smart glasses, like the Microsoft HoloLens 2. They are suitable for the training learners on new task as well as for routine tasks. With the help of visual aids in form of step cards information on e. g. operating a machine can be provided on the spot. A navigation from one step card to another can be done by touch or by voice.

The necessary information includes written tasks, pictures, and videos as well as, if available, 3D information. With a desktop app, like for Microsoft Guides, available digital media can be integrated by drag and drop as well as guidance step can be defined as well as further enriched with knowledge quizzes.

Step cards are suitable for the provision of rather technical knowledge to operate or maintain a machine. By the integration of videos also non-documented knowledge on handling a machine can be provided.

3D Printing is short for “three-dimensional” printing. Often it is called additive manufacturing since the product is built layer by layer.

3D printers come in all shape and sizes.

The most common printed materials are thermoplastics like PLA (Poly Lactic Acid) and ABS (Acrylonitrile Butadiene Styrene). For example, Lego bricks are made of ABS.

IoT stands for internet-of-things. This includes a network of intelligent sensors, which process the data normally directly on the machine or by communication with the cloud. Potential fields of application are rather industrial environments like chemical or automotive plants. Intelligent sensors could include sensors measuring pH, temperature, or humidity.

A pedagogical-sound training application can focus on data visualisation, which helps the learner to critically reflect the data presented. The combination of IoT with tablets and smart glasses enables users to control a sensor over a holographic dashboard (see below).

From 19. and 20.05.2022 the partner organisation in DIOS from:

met during a hybrid meeting in Pardubice/Czech Republic to discuss the pedagogical-sound implementation of modern technology (AR, VR, 3D printing, IoT) in practical training. The focus is on training in the fields of chemistry (lab and training plant), IT and mechatronics.

The partners also discussed the state and the plans for their learning labs to integrate industry specific trainings with modern media in their organisational process. Aim is to train own trainers and teachers as well as to offer tailor-made trainings to third parties, like training companies.

The provision of knowledge from expert to learner in practical training is often a mix of verbal and paper-based instructions. There are situations, where the apprentice needs on spot support, but the trainer is spatially not there.

A solution which allows integration of remote support by using smart glasses like the Microsoft HoloLens 2 and a suitable app like Remote Assist, can bridge the gap. These is an easy way to connect trainer and apprentice or apprentice with each other in real time. It is the choice for carrying out subsequent tasks in a guided way. Audio-visual support by voice and by the integration of simple holograms in the field of view of the guided apprentice collaborative and instructive learning is supported. These 1:1 way of learning binds an expert, but almost no preparation time is needed

Remote Assist or Remote support is the choice for the provision of rather technical knowledge to operate or maintain a machine. These fosters the provision of documented and non-documented knowledge from the expert to the learner.

From 31.10.-04.11.2022 10 teachers and trainers from NL, DE, SI, and CZ participated in media-pedagogical training in Limassol/Cyprus. It served as an introduction to pedagogical-sound media use in practical training in chemistry, IT, and mechatronics as well as an appetizer to explore further use of modern educational technologies in VET.

It kick-started with a brief introduction in the DIOS pedagogical guidelines and the presentation of sample scenarios. These scenarios focussed on the integration of AR, VR, 3D printing and IoT in practical training in the focus fields. After that hands-on sessions on the used technologies were carried out. These helped the teaching personal present to develop course specific and tailor-made lessons plans to integrate e. g. 3D printing in chemistry glasses or how to create and assemble an 3D printed IOT computer.

From 07. and 08.12.2022 the partner organisation in DIOS from:

met in Ulft/Netherlands to discuss the operation of the 5 learning labs in the five partner countries. The NL- Partner provided first hand insights on building and running a learning lab, which the other partners can now adapt partly or fully in their school environments. These includes also to create visual and audio content like a podcast. The updates will be visible on the www.dioslab.com soon.

On March 28, 2023, the final conference of the EU project DIOS took place in the Pullmann Hotel in Dresden as part of the Excellence Forum for the integration of the latest digital media into practical training.

Around 30 people from business, research and education policy got an exclusive insight into the simple and educational integration of the latest educational technologies in learning and work processes. The focus was on the low-threshold integration of data glasses, 360° videos, intelligent sensors (IoT) and 3D printing in chemistry, mechatronics, and IT.

After the keynote on the topic "Are smart glasses already part of our new world of work" by Mr. Eckhard Wittstock (TU Chemnitz), Dr. Torsten Dunkel from the National Agency at the Federal Institute for Vocational Training. He referred to funding opportunities for project plans and to the entitlement generated by the funding body as a result of the DIOS project application, which was rated very well. Afterwards, Dr. Harry Brink from Graafschap College gave an overview and insight into how modern vocational training works in the Netherlands.

Then, the participants of the Excellence Forum learned first-hand from five practical examples (including a chemical laboratory and chemical plant) how modern technologies can be successfully integrated. This took place in the context of a structured qualification of vocational training staff in so-called teaching and learning laboratories.

The laboratories are anchored spatially and organizationally in the respective institution to scout out new technologies, try them out and create teaching and learning materials that are as tailor-made as possible. During the event, all participants had the opportunity to try out the presented technologies themselves in the Experience Area and to ask the representatives of the DIOS partner institutions from Germany, the Netherlands, Slovenia, the Czech Republic and Cyprus questions about media creation and scaling place.